“Revolutionizing Manufacturing: How SLS 3D Printing Services Are Changing the Game”

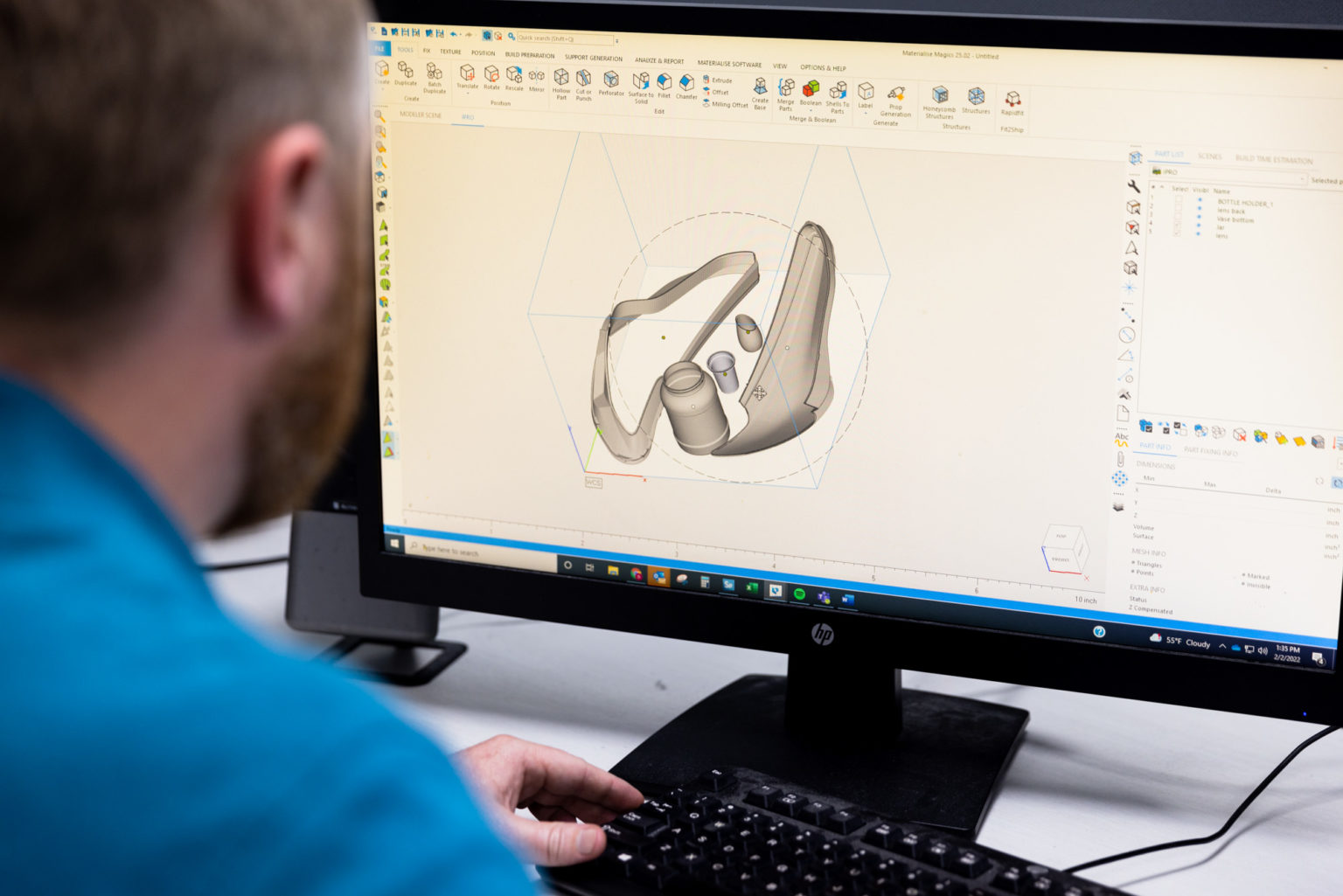

Manufacturing processes have significantly evolved over the years, with technological advancements playing a crucial role in shaping the industry. One particular innovation that is revolutionizing manufacturing is Selective Laser Sintering (SLS) 3D printing services. SLS 3D printing is a cutting-edge technology that utilizes a high-powered laser to sinter powdered materials, such as nylon or metal, layer by layer to create intricate and complex 3D objects. This additive manufacturing process offers numerous advantages over traditional manufacturing methods and is changing the game in various industries. If you want SLS 3D printing services that are top-notch and affordable, you can check this website https://quickparts.com/sls-printing/.

One of the key benefits of SLS 3D printing services is the ability to create highly complex geometries that would be impossible or extremely costly to produce using traditional manufacturing techniques. This freedom of design allows for greater innovation and creativity in product development, enabling manufacturers to optimize the performance and functionality of their products. Additionally, SLS 3D printing is a rapid prototyping technique, which means that prototypes and parts can be produced quickly and at a lower cost compared to traditional methods. This speed and cost-effectiveness make SLS 3D printing ideal for iterative design processes and reducing time-to-market for new products.

Another advantage of SLS 3D printing services is the ability to produce custom and on-demand parts with minimal setup and tooling. Traditional manufacturing processes often require expensive tooling and molds to produce custom parts, which can be time-consuming and costly. With SLS 3D printing, parts can be produced directly from a digital file, eliminating the need for tooling and reducing lead times. This capability is especially beneficial for industries that require low-volume production or customized parts, such as aerospace, automotive, and medical devices.

In conclusion, SLS 3D printing services are revolutionizing manufacturing by offering a more flexible, cost-effective, and sustainable approach to production. The benefits of SLS 3D printing, such as design freedom, rapid prototyping, custom part production, improved material properties, and environmental friendliness, make it a game-changer for various industries. As technology continues to advance and the demand for innovative and efficient manufacturing solutions grows, SLS 3D printing is poised to play a significant role in shaping the future of manufacturing. Manufacturers that embrace SLS 3D printing services stand to gain a competitive edge in the market by delivering high-quality products faster and more efficiently than ever before.